In today’s competitive market, packaging is more than protection- it’s your brand’s voice. At IPAK, we deliver comprehensive structural packaging design and manufacturing solutions that enhance product protection, brand visibility, and customer engagement.

Customized Packaging Solutions, From Concept to Creation

Our in-house structural packaging engineers collaborate closely with you to craft innovative, tailor-made packaging solutions. We start with a deep understanding of your business goals, ensuring every design aligns with your brand’s vision and objectives.

Our Tailored Process:

- Consultation & Discovery: We delve into your specific needs, exploring your brand values, customer experience goals, and desired outcomes.

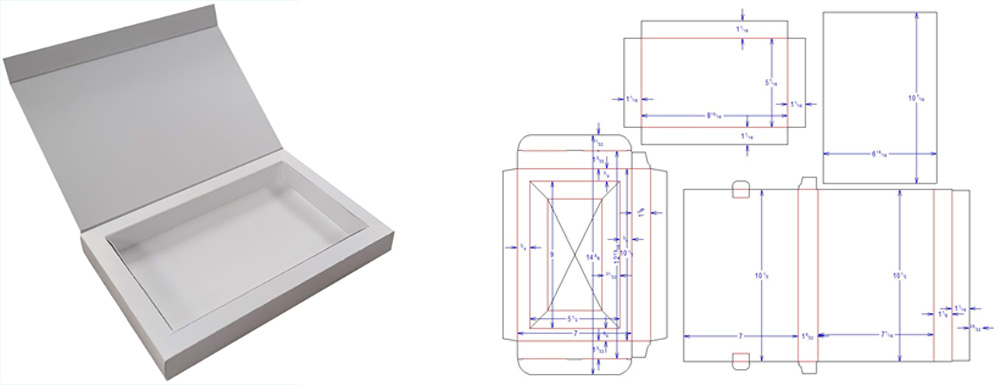

- CAD-Based Design: Utilizing advanced software, we create structurally sound and visually compelling packaging designs.

- Material Selection: We source high-quality, sustainable materials that balance strength, aesthetics, and environmental responsibility.

- Prototype Approval: We provide physical prototypes for your review, ensuring every detail meets your expectations.

- Seamless Production & Fulfillment: Our state-of-the-art, in-house facilities manage every aspect of production, from printing and die-cutting to assembly and delivery.

Our Comprehensive Capabilities:

- State-of-the-Art In-House Manufacturing: Over 90 pieces of equipment, ensuring seamless production and stringent quality control.

- Sustainable Solutions: Commitment to eco-friendly practices, including FSC-certified materials and energy-efficient processes.

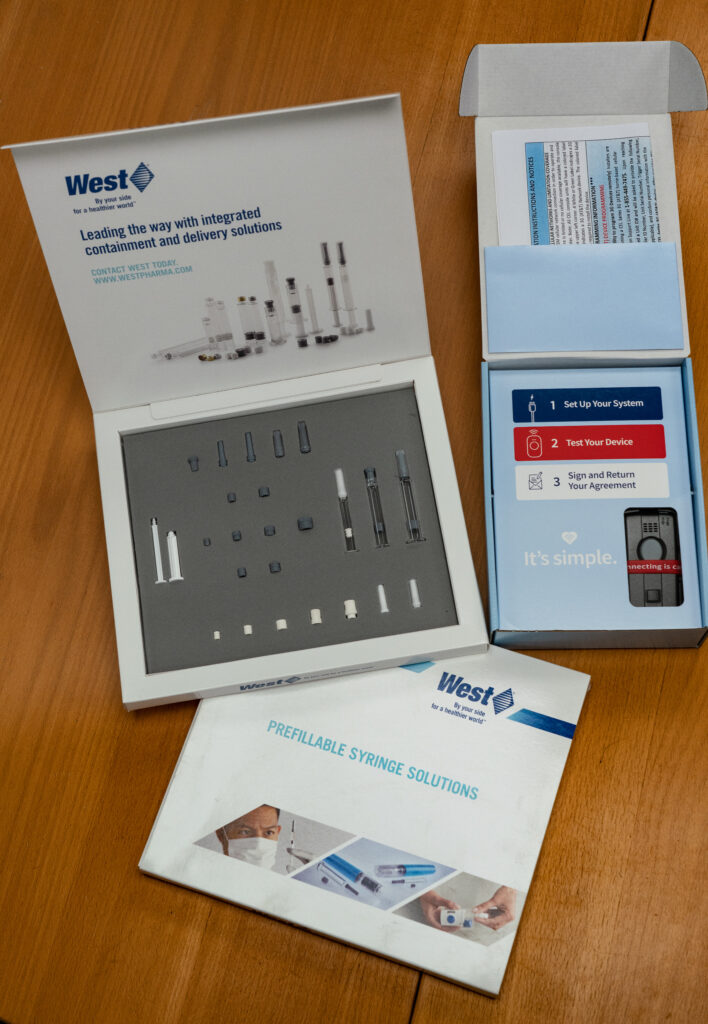

- Promotional & Specialty Packaging: Creating memorable packaging for gift-with-purchase, promotional kits, and more.

- End-to-End Services: High-speed digital printing, precise die-cutting, assembly, logistics, and delivery.

Why Choose IPAK?

- We are the manufacturer! With 90 pieces of equipment in-house, we produce packaging, displays, ridged boxes, set-up boxes, slip cases and more.

- Customized Solutions: Tailored packaging that perfectly fits your product and brand. Optimal layout for the most cost effective printing & diecutting.

- In-House Expertise: Expert engineers and comprehensive manufacturing capabilities.

- Sustainability: Eco-conscious solutions that align with your corporate goals.

- Collaborative Approach: Transparent communication and flexibility throughout the process.

- Rigorous Quality Control: Ensuring every packaging solution meets the highest standards.

- Scalable Solutions: Adaptable services for small runs to large-scale production.

Partner with IPAK to transform your packaging into a powerful brand asset. Contact us today to discuss your project.